Sheet hlau yog dab tsi? Sheet hlau yog cov txheej txheem ua haujlwm txias rau cov ntawv hlau (feem ntau tsawg dua 6 hli), suav nrog kev txiav, xuas nrig ntaus / txiav / sib xyaw, folding, vuam, riveting, splicing, sib sau.

Nws cov yam ntxwv yog:

1. uniform thickness. Rau ib feem, lub thickness ntawm tag nrho cov seem yog tib yam

2. lub teeb yuag, siab zog, conductivity, tsis tshua muaj nqi, loj-scale ntau lawm kev ua tau zoo

- Kev siv technology -

1. txiab

Cov cuab yeej ntawm cov txheej txheem shearing yog lub tshuab shearing, uas tuaj yeem txiav cov ntawv hlau rau hauv cov duab yooj yim. Qhov zoo yog: cov nqi ua haujlwm tsawg; Qhov tsis zoo: qhov tseeb yog qhov dav dav, kev txiav muaj burrs, thiab cov duab txiav yog cov duab plaub yooj yim lossis lwm cov duab yooj yim uas muaj cov kab ncaj.

Ua ntej cov txheej txheem txiav, qhov nthuav dav ntawm cov khoom yuav tsum raug xam, thiab qhov loj ntawm qhov nthuav dav yog cuam tshuam nrog lub vojvoog dabtsi yog khoov, khoov lub kaum sab xis, cov khoom siv phaj thiab phaj thickness.

2. puj

Cov cuab yeej ntawm cov txheej txheem xuas nrig ntaus yog xuas nrig ntaus xovxwm, uas tuaj yeem ua cov txheej txheem hlais rau hauv cov duab. Stamping ntau yam duab xav tau cov pwm sib txawv, cov pwm pwm muaj qhov puag ncig, qhov ntev puag ncig, convex; High precision.

Boss: Cov khoom tsis raug tshem tawm, xyuam xim rau qhov siab ntawm tus thawj coj yog txwv, muaj feem xyuam rau cov khoom ntawm lub phaj, lub thickness ntawm lub phaj, lub kaum sab xis ntawm tus thawj bevel, thiab lwm yam.

Muaj ntau hom convex, nrog rau qhov kub dissipation qhov, mounting qhov, thiab lwm yam. Vim yog lub zog ntawm dabtsi yog khoov, ntug ntawm lub qhov tsim yog txwv los ntawm lub phaj ntug thiab khoov ntug.

3. Laser txiav

Cov cuab yeej ua haujlwm: laser txiav tshuab

Rau kev txiav, xuas nrig ntaus cov txheej txheem tsis tuaj yeem ua kom tiav cov ntaub ntawv tshem tawm, lossis hardness yog ib qho yooj yim rau kev puas tsuaj rau pwm ntawm lub phaj, xws li cov ces kaum, los yog tsis muaj pwm npaj los nias cov duab uas yuav tsum tau, koj tuaj yeem siv laser txiav. ua kom tiav cov txheej txheem ntawm cov khoom ua ntej khoov

Qhov zoo: tsis muaj burrs, siab precision, tuaj yeem txiav cov duab, xws li nplooj, paj, thiab lwm yam. Qhov tsis zoo: Cov txheej txheem siab nqi

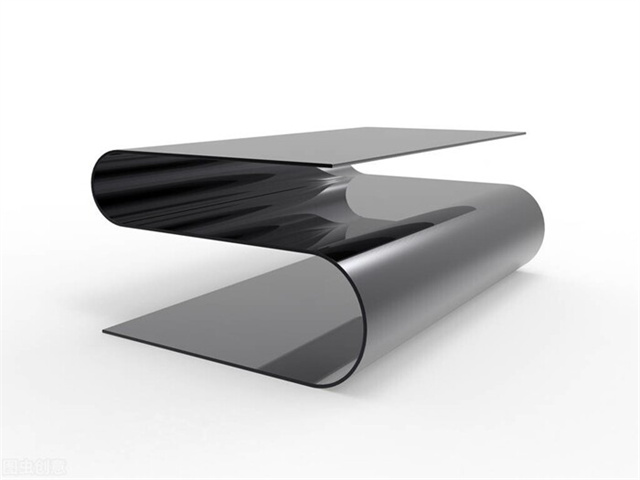

4. Khoov

Cov cuab yeej ua haujlwm: tshuab dabtsi yog khoov, phaj dov tshuab

Lawv tuaj yeem quav lossis yob cov ntawv hlau rau hauv cov duab uas xav tau, yog cov txheej txheem tsim cov khoom; Cov txheej txheem ntawm txias nias cov ntawv hlau los ntawm lub tshuab dabtsi yog khoov thiab cov riam qis kom nws deformable thiab tau txais cov duab uas xav tau yog hu ua dabtsi yog khoov.

dabtsi yog khoov yog kauj ruam kawg ntawm daim ntawv hlau txoj kev, qhov chaw yuav tsim thiab dabtsi yog khoov molding yuav tsum tau them sai sai mus rau ob peb lub ntsiab lus, cov nram qab no me me series thiab koj hais.

① Tsis muaj cov khoom siv

Tus thawj coj yog siab dhau, tshaj qhov ductility ntawm cov khoom, tus thawj coj feem ntau yog siv rau qhov loj me ntawm lub ncoo qhov siab los yog kom tsis txhob muaj teeb meem kev teeb tsa, yog li tus thawj coj tuaj yeem ua yam tsis hloov cov qauv sab hauv ntawm cov khoom thiab tsis cuam tshuam. lub cev muaj zog. Piv txwv li, lub kaum sab xis ntawm lub convex cone thiab lub datum nto yog 45 °, thiab qhov siab yog 3 npaug ntawm lub thickness ntawm lub phaj.

②Redundant cov ntaub ntawv

Cov khoom siv tsis tu ncua feem ntau muaj ntau qhov nkhaus ntug theem kaw, uas feem ntau yog vim cov txheej txheem tsis raug lossis kos duab yuam kev

③ Khoov txwv

Feem ntau cov tshuab dabtsi yog khoov muaj qee yam kev txwv ntawm kev khoov.

Unilateral qhov siab: nyob ntawm qhov loj ntawm lub tshuab dabtsi yog khoov thiab qhov siab ntawm cov riam sab sauv, cov tshuaj tuaj yeem ua tau ntau lub kaum sab xis loj

Qhov siab ntawm ob sab: tsis siab tshaj qhov siab unilateral, ntxiv rau tag nrho cov kev txwv ntawm qhov siab unilateral, tab sis kuj los ntawm cov kev txwv hauv qab: khoov qhov siab < hauv qab ntug

④ Weld

Txij li cov ntawv hlau yog tsim los ntawm cov ntawv hlau los ntawm kev khoov, kev sib cuag ntawm ntug khoov tsis raug kaw yam tsis muaj kev sib txuas nyuaj, yog tias tsis kho yuav cuam tshuam rau lub zog, feem ntau txoj kev kho yog vuam, cov kev cai ntawm cov duab kos yog: vuam Angle. , vuam Angle, puag ncig.

5. Kev kho deg

Vim tias cov ntawv hlau yog nyias, tsis haum rau kub dip galvanizing, cov txheej txheem kev kho saum npoo yog: electrostatic tsuag, xim nrog engineering, cov txheej txheem no yog tsim rau cov ntaub ntawv rau saum npoo ntawm cov xim dub.

Chaw tsim tshuaj paus ntawm sheet hlau ua

RM Manufacturing nyob rau hauv Chengdu, Sichuan Province, lub teb chaws ntawm abundance, nyob rau hauv lub southwest economic cheeb tsam, yooj yim kev thauj mus los. Lub tuam txhab npog thaj tsam ntawm 37,000 square metres thiab yog thawj zaug ntawm nws ob cov nroj tsuag hauv kev lag luam high-precision sheet hlau ua kev lag luam.

Kev koom nrog hauv cov khoom lag luam yog lub tshuab ntxhua khaub ncaws tsis siv neeg, dej ntsuas ntsuas zoo, lub zog hloov pauv hloov txee, ntse kev pabcuam tus kheej vending tshuab, tsheb them pawg, kev pabcuam tus kheej lub tsheb ntxhua khaub ncaws, khib nyiab rov siv lub tshuab, ATM plhaub, CNC khoom plhaub, locker, lub txee fais fab, kev sib txuas lus, kev kho mob, thiab lwm yam, rau cov khoom siv tsis zoo ntawm tus kheej, muab kev daws teeb meem tag nrho.

Post lub sij hawm: Aug-07-2023